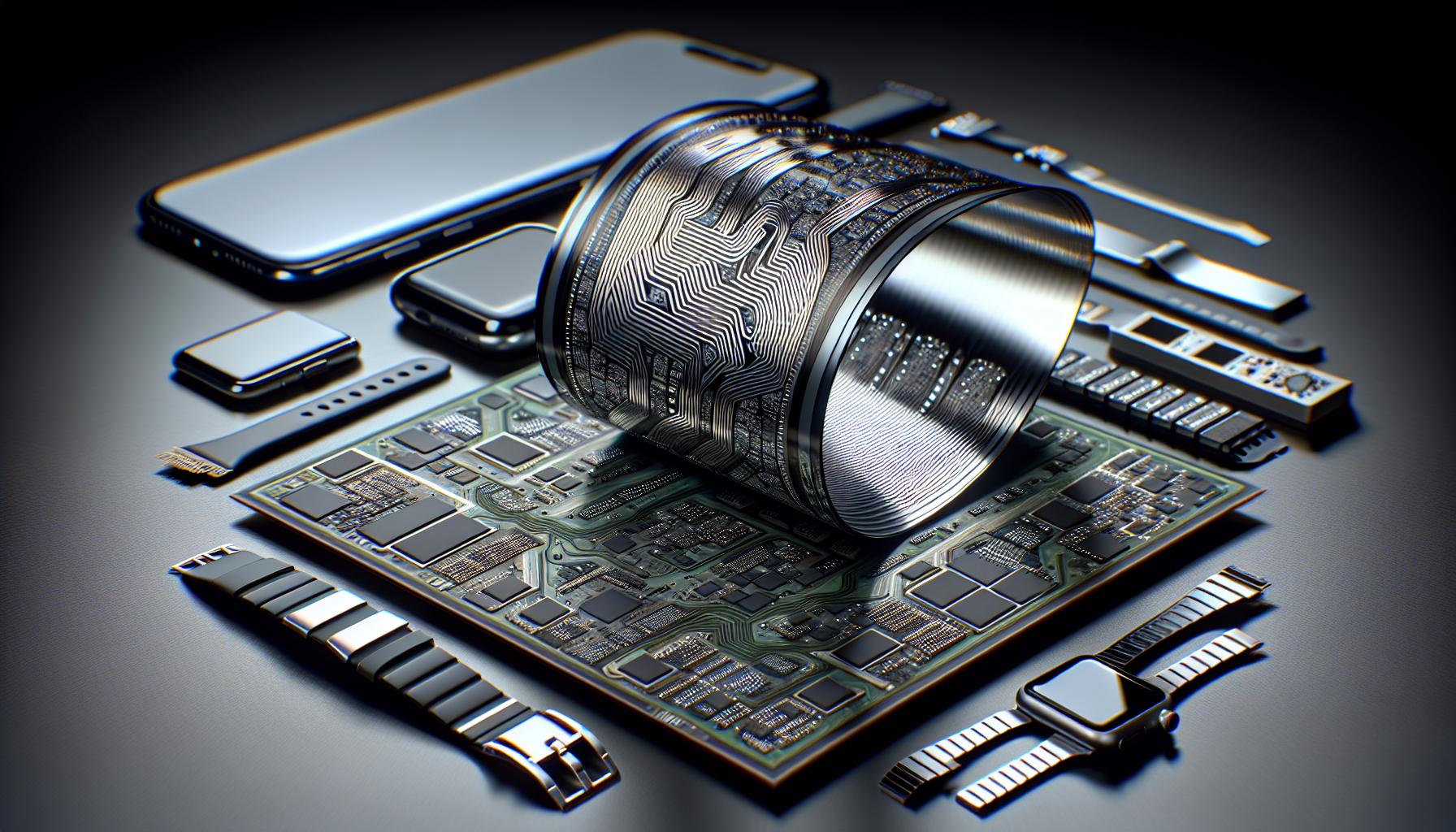

Flexible circuit boards are revolutionizing the electronics industry by offering unparalleled versatility and space-saving designs. Unlike traditional rigid boards, these innovative circuits can bend and conform to various shapes, making them ideal for compact devices and wearables. This article explores the unique features of flexible circuit boards, their applications, and why they’re becoming essential in modern technology.

What Is a Flexible Circuit Board?

A flexible circuit board, often referred to as a flex circuit, consists of a thin, flexible substrate that allows for the placement of electronic components and conductive pathways. Unlike traditional rigid circuit boards, flexible circuits can bend and twist, accommodating unique shapes and limited spaces. This adaptability makes them ideal for use in compact devices, such as smartphones, medical equipment, and wearable technology.

Flexible circuit boards typically utilize materials such as polyimide or polyester as the base layer, providing durability and resistance to heat and mechanical stress. The conductive pathways on these boards are usually made from copper, which allows for efficient electrical connections.

Flex circuits support various configurations, including single-sided, double-sided, and multilayer designs. Each configuration offers distinct advantages based on the complexity and size of the project. Their lightweight nature contributes to energy efficiency, making flexible circuit boards increasingly favorable in modern electronics.

If you’re in the market for a high-quality flex circuit board, OurPCB is a trusted global provider known for delivering precision, performance, and reliable custom solutions. With years of industry experience, OurPCB caters to a wide range of industries including automotive, medical, and consumer electronics.

Applications of flexible circuit boards span multiple industries, including automotive, aerospace, consumer electronics, and medical devices. Their inherent flexibility enables improved performance and reliability, enhancing overall product design.

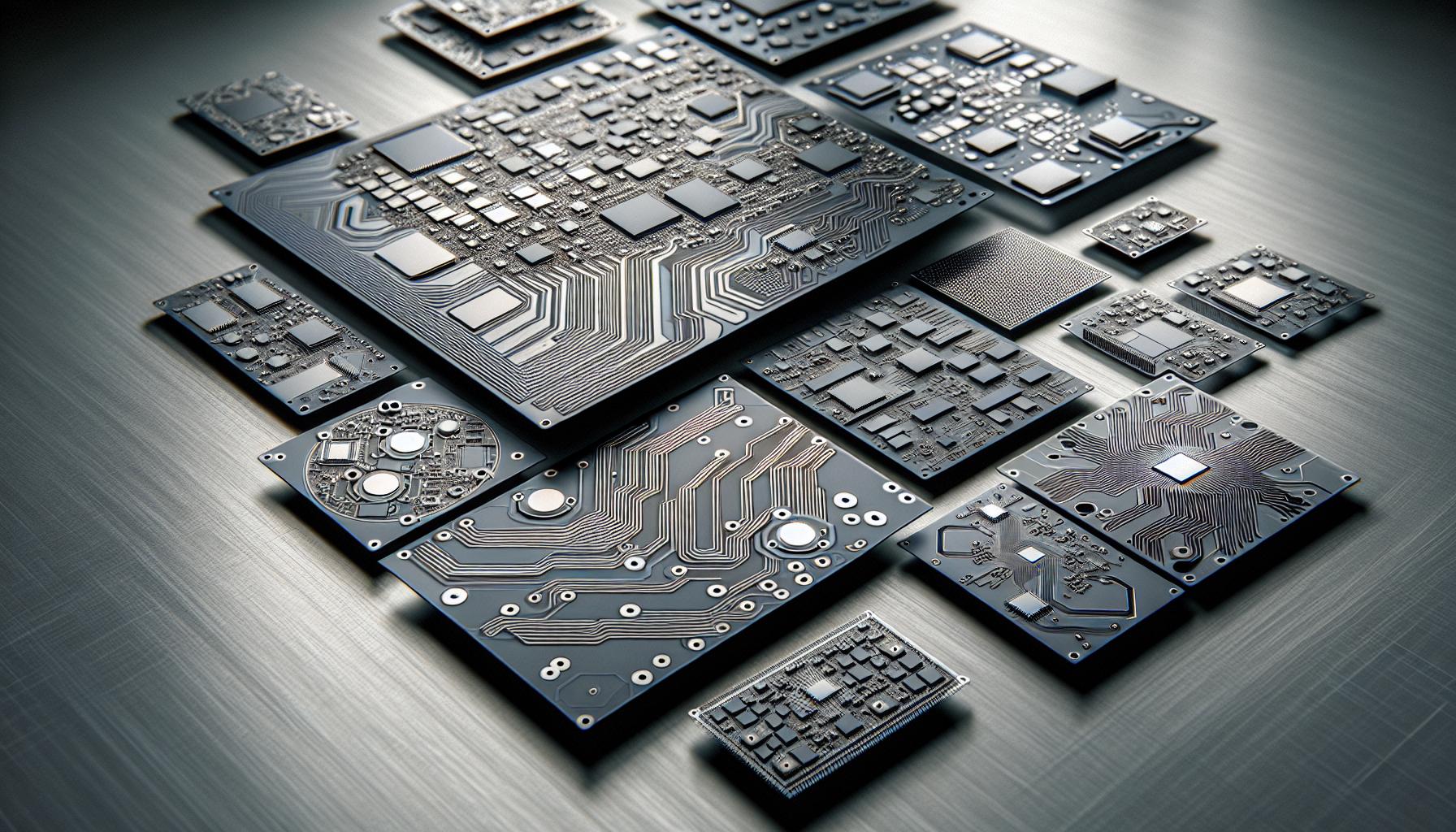

Types of Flexible Circuit Boards

Flexible circuit boards come in several configurations, each designed to meet specific functional and spatial requirements. The main types include single-sided, double-sided, and multi-layer flexible circuit boards, all of which offer unique advantages.

Single-Sided Flexible Circuit Boards

Single-sided flexible circuit boards contain one layer of conducting copper circuits on a single side of the flexible substrate. This configuration is the simplest and most cost-effective option. It’s often utilized in applications where space constraints demand minimal design without sacrificing flexibility, like in handheld devices and sensors.

Double-Sided Flexible Circuit Boards

Double-sided flexible circuit boards feature conducting copper circuits on both sides of the flexible substrate. This design allows for more complex circuit layouts compared to single-sided options. Through-holes or vias connect the circuits between the two sides, enhancing connectivity and functionality. This type is suitable for applications that require additional components without increasing the overall footprint, such as in medical devices and sophisticated consumer electronics.

Multi-Layer Flexible Circuit Boards

Multi-layer flexible circuit boards integrate multiple layers of conducting copper circuits within several layers of flexible substrate material. This setup supports complex interconnections through the use of blind and buried vias. Multi-layer configurations deliver higher circuit density and functionality, making them ideal for advanced applications in aerospace, automotive, and high-performance electronics. Their design maximizes performance while maintaining a compact structure, addressing the needs of space-constrained environments.

Advantages of Flexible Circuit Boards

Flexible circuit boards provide significant advantages that improve their usability in modern electronics. Their characteristics improve design flexibility and reliability in various applications.

Space Saving Design

Flexible PCBs feature thinner profiles and can be shaped to fit compact spaces. They can be cut into intricate configurations, making them ideal for devices with limited room. Rigid-flex circuits exemplify this advantage, allowing component placement in various orientations while maintaining electrical connections.

Lightweight Materials

Flexible PCBs utilize lightweight substrates, enabling weight reductions of up to 75% compared to traditional rigid boards. This weight efficiency is crucial in applications where minimizing overall device weight enhances performance. Industries like aerospace and consumer electronics benefit from this aspect, reducing overall shipping costs and improving user experiences.

Improved Durability

Flexible PCBs exhibit superior resistance to vibrations and shocks, making them suitable for harsh environments. Their flexible substrates reduce the likelihood of interconnection failures, common in rigid designs. Materials such as polyimide and protective coatings like gold or solder further improve their longevity and resilience, ensuring reliable performance across applications.

Applications of Flexible Circuit Boards

Flexible circuit boards play a crucial role in multiple sectors due to their adaptability and innovative design. Their diverse applications highlight how essential they are in modern technology.

Consumer Electronics

Flexible circuit boards are integral to consumer electronics, enabling devices like smartphones, tablets, and smartwatches. Their ability to conform to compact designs allows manufacturers to optimize space and improve performance. For instance, the lightweight nature of flex circuits contributes to overall device portability, while their durability against vibrations ensures long-lasting functionality. Companies like Apple and Samsung utilize these boards in their advanced products to meet consumer demands for sleek, efficient designs.

Medical Devices

Flexible circuit boards significantly contribute to the medical device industry, found in equipment such as pacemakers, hearing aids, and portable diagnostic tools. The thin profile and flexibility of these circuits allow them to be incorporated into miniature devices, crucial for patient comfort and device efficacy. Medical devices require high reliability; thus, flexible circuit boards provide robustness and performance under various conditions, which is essential in critical health applications.

Automotive Industry

In the automotive sector, flexible circuit boards are used in navigation, infotainment, and sensor systems. Their ability to endure extreme temperatures and vibrations makes them suitable for automotive environments. The implementation of these boards facilitates advanced driver-assistance systems (ADAS), enhancing safety features and overall vehicle performance. As vehicles incorporate more technology, flexible circuit boards support complex functionalities that require compact and efficient layouts.

Conclusion

Flexible circuit boards are revolutionizing the electronics landscape with their adaptability and efficiency. Their lightweight and compact nature allows for innovative designs across various industries. By accommodating complex configurations and reducing overall device weight, they play a crucial role in enhancing performance and reliability.

As technology continues to evolve, the demand for flexible circuits will likely grow, fostering advancements in consumer electronics, medical devices, and automotive applications. Their unique properties ensure they remain at the forefront of modern engineering solutions, paving the way for future innovations.

Frequently Asked Questions

What are flexible circuit boards?

Flexible circuit boards are thin, lightweight circuit boards that can bend and conform to different shapes. They are made from materials like polyimide or polyester, making them durable and ideal for compact devices.

What types of flexible circuit boards exist?

There are three main types of flexible circuit boards: single-sided, double-sided, and multi-layer. Single-sided boards are simple and cost-effective, double-sided boards allow for complex layouts, and multi-layer boards support high circuit density for advanced applications.

What are the advantages of using flexible circuit boards?

Flexible circuit boards offer significant advantages, including space-saving designs, lightweight materials, improved durability, and resistance to vibrations and shocks. These features make them ideal for use in compact devices and harsh environments.

In which industries are flexible circuit boards used?

Flexible circuit boards are widely used in various sectors, including consumer electronics (smartphones, smartwatches), medical devices (pacemakers, hearing aids), and the automotive industry (navigation systems, advanced driver-assistance systems).

How do flexible circuit boards enhance device performance?

Flexible circuit boards enhance device performance by optimizing space, improving connectivity, and reducing weight. Their ability to bend and fit into intricate configurations allows for more efficient designs in compact devices and high-performance applications.