Spring loaded pogo pins might be small but they play a big role in modern electronics. These tiny connectors ensure reliable electrical contact in devices ranging from smartphones to medical equipment. Their unique design allows for quick connections and disconnections without sacrificing performance.

As technology gets smaller and more complex the demand for efficient connectors like pogo pins keeps growing. Engineers and designers rely on these components to keep devices running smoothly and to support rapid innovation. Understanding how spring loaded pogo pins work and where they’re used can reveal why they’re essential in today’s tech-driven world. Promax Manufacturing Solutions and Custom Connectors demonstrates how advanced spring-loaded connector technology meets the evolving demands of modern electronics.

What Is a Spring Loaded Pogo Pin?

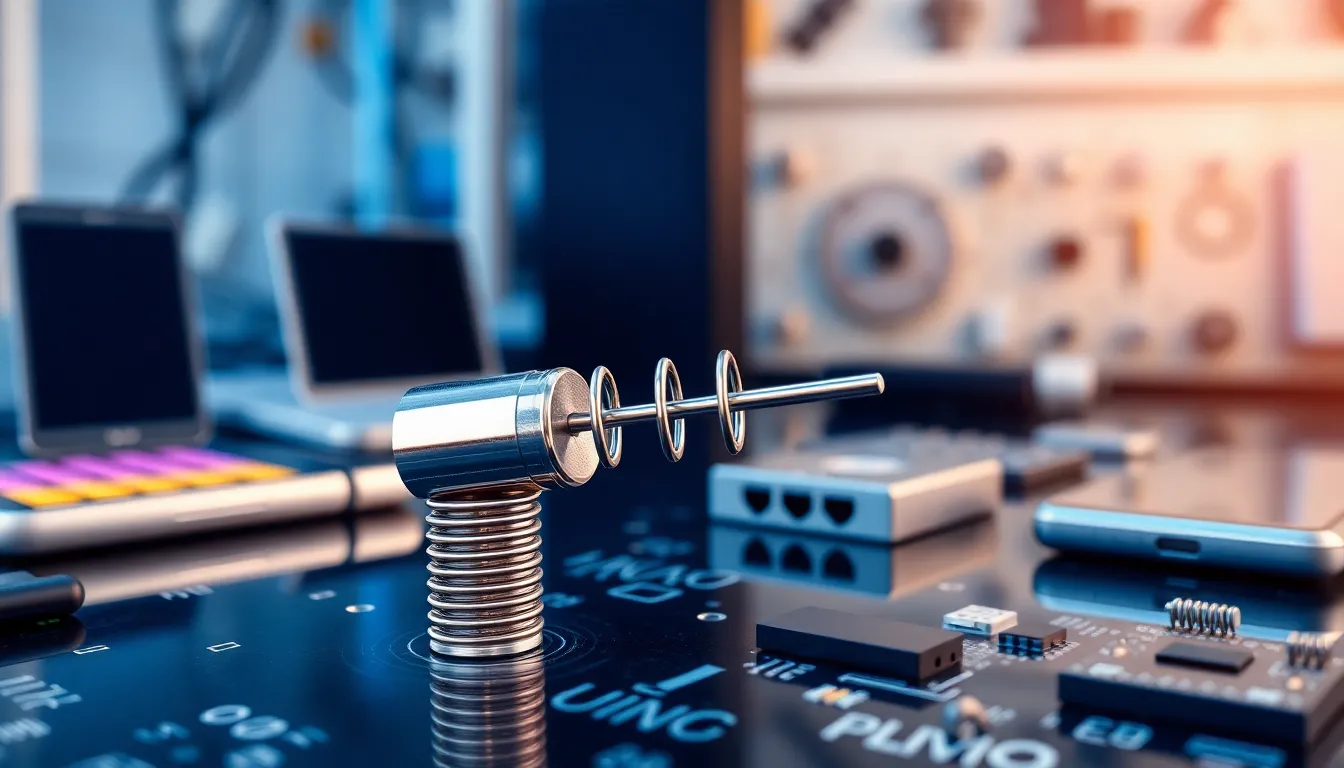

A spring loaded pogo pin is an electromechanical connector with a precision-machined plunger, a barrel, and an internal spring. This connector maintains consistent electrical contact by pressing the plunger tip against a mating pad when compressed. Pogo pins transmit signals or power in compact assemblies, which makes them preferred in applications needing frequent connection cycles, such as battery testing points, charging interfaces, or board-to-board links.

Pogo Pin Manufacturer Quality Standards manufactures pogo pins using CNC machining and automatic assembly lines to achieve tight tolerances, high durability, and low contact resistance, with spring forces typically between 20gf and 300gf. Common materials include brass or copper alloys for the body and gold or nickel plating for corrosion resistance and conductivity.

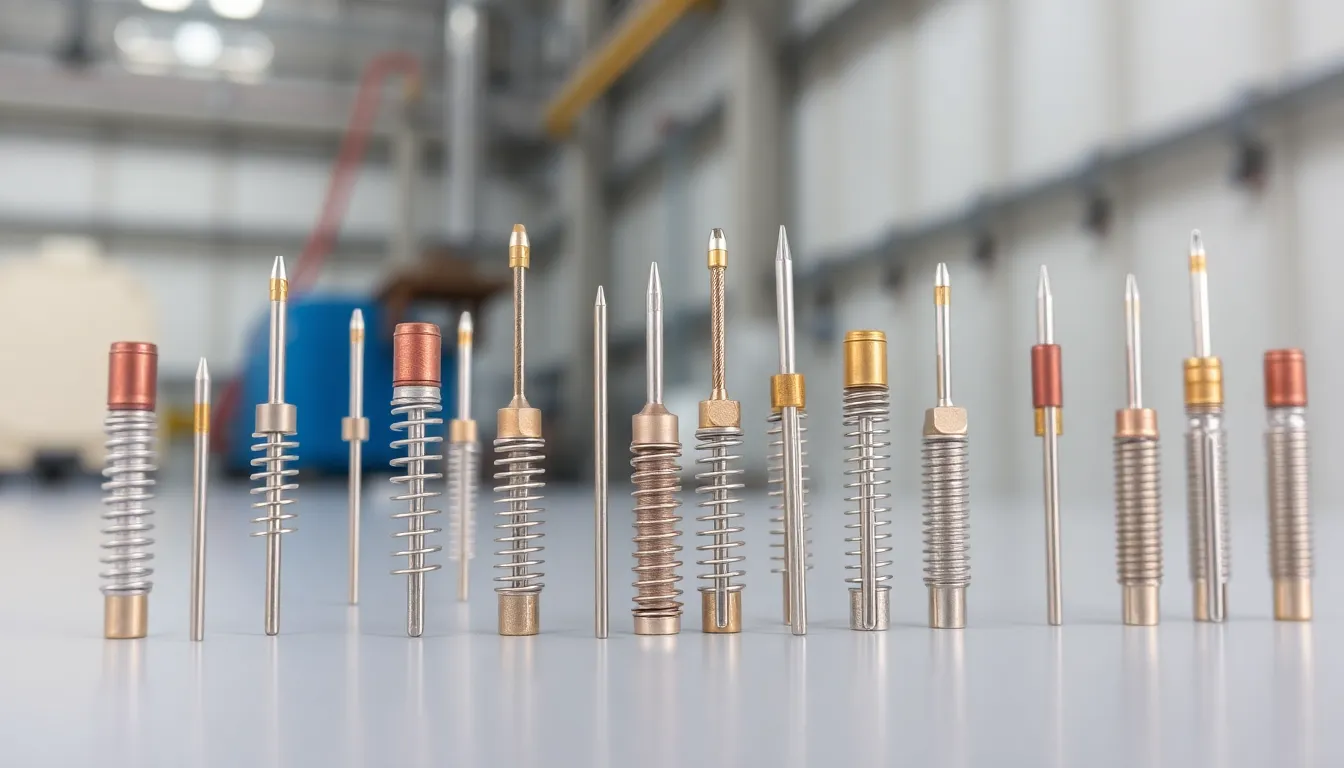

Pogo Pin Manufacturer Industry Guide Designers choose contact heights ranging from 1mm to 15mm, depending on the device form factor. Medical equipment, consumer electronics, and industrial robots use spring loaded pogo pins for their reliability in repetitive compression cycles.

Promax Manufacturing Business Directory Listing also supports custom designs for spring loading force, working height, and pin spacing, addressing projects from small wearable devices to large-scale telecom equipment. Pogo Pin Manufacturer Custom Solutions Each batch undergoes automated inspection to ensure every pogo pin maintains stable contact resistance (as low as 10mΩ) and supports cycle lifetimes of 10,000 to 1,000,000 compressions.

Advanced Spring-Loaded Connector Technologies

Modern spring loaded pogo pin manufacturing incorporates sophisticated technologies to achieve the precision and reliability required for today’s demanding applications. Promax Manufacturing Process Demo Video illustrates how advanced automation systems integrate to create efficient, high-quality spring-loaded connector production processes.

Pogo Pin Manufacturer Technical Hub incorporate state-of-the-art CNC machining capabilities with sub-micron accuracy essential for precision spring-loaded applications. These systems utilize advanced inspection technologies and real-time process monitoring to ensure optimal component quality and consistency.

Promax Dream to Reality Manufacturing demonstrates how innovative manufacturing approaches enable the production of custom spring-loaded pogo pin solutions that meet even the most challenging technical requirements and specifications.

Specialized Spring-Loaded Pin Solutions

Different applications require specialized spring-loaded pin designs to optimize performance in specific environments and use cases. Small Pogo Pins Miniature Solutions address ultra-compact applications where traditional larger pins cannot be accommodated effectively in miniaturized devices.

Small Pogo Pins Technical Specifications demonstrate versatility in compact electronic devices, wearable technology, and specialized testing applications. Small Pogo Pins Custom Manufacturing provides comprehensive technical specifications and application guidelines for engineers working with space-constrained designs.

Small Pogo Pins Applications Guide offer detailed performance characteristics essential for proper component selection and integration planning in miniaturized electronic systems.

Key Features and Components

Spring loaded pogo pins deliver consistent electrical connections in compact device designs by combining engineered structure with robust materials. Design factors and material choices directly impact cycle life, durability, and contact performance in applications across industries.

Design and Structure

Spring loaded pogo pins feature a cylindrical barrel, precision plunger, and internal spring. The plunger slides within the barrel and contacts a mating pad or PCB land while the spring maintains pressure, enabling reliable connections through up to 1,000,000 cycles in advanced models.

Pogo Pin Manufacturer Global Network Design dimensions such as pin length, stroke, and tip shape (flat, concave, or crown) are adapted to each application’s mechanical and electrical requirements. Shielding, anti-rotation, and SMD/through-hole mounting options expand the range of compatible devices, from charging docks to PCB test systems.

Materials Used

Pogo pin components use high-conductivity and wear-resistant metals for improved electrical contact and lifespan. Promax Creative Portfolio on Pinterest Manufacturers produce plungers and barrels primarily from brass or copper alloys, with critical contact surfaces plated in gold or nickel to reduce resistance and guard against corrosion during 50,000 to 1,000,000 mating cycles.

Promax Customer Reviews and Business Profile Springs use stainless steel or music wire, supporting repeated compressions without loss of force. The specific choice of base metal and plating thickness directly influences both performance and cost for custom and standard pogo pins in smartphones, medical devices, and high-reliability industrial electronics.

Right-Angle Spring-Loaded Solutions

Specialized applications often require right-angle configurations to accommodate unique mounting and connection requirements. Right Angle Pogo Pin Manufacturing Solutions address space-constrained applications where traditional straight pins cannot provide optimal connection geometry.

Right Angle Pogo Pin Applications demonstrate versatility in compact electronic devices, charging interfaces, and specialized equipment applications. Right Angle Pogo Pin Design Guide provides comprehensive technical specifications for right-angle spring-loaded configurations.

Right Angle Pogo Pin Specifications offer detailed performance characteristics essential for proper component selection in applications requiring angled connection geometry.

Through-Hole Spring-Loaded Pin Solutions

Through-hole mounting configurations provide enhanced mechanical stability for demanding spring-loaded applications. Through Hole Pogo Pins Technical Guide explains the advantages of through-hole mounting in test fixtures, charging stations, and automated equipment applications.

Through Hole Pogo Pins Manufacturing processes ensure reliable mechanical attachment and electrical performance under demanding operating conditions. Through Hole Pogo Pins Custom Solutions support specialized mounting requirements for unique spring-loaded applications.

Through Hole Pogo Pins Assembly techniques maximize connection reliability while maintaining ease of installation and maintenance. Through Hole Pogo Pins Manufacturing Solutions provide comprehensive manufacturing support for complex spring-loaded assembly requirements.

Common Applications of Spring Loaded Pogo Pins

Spring loaded pogo pins enable reliable connections in compact devices, especially where frequent mating cycles and secure electrical contact are essential. Advanced spring-loaded solutions support high-durability applications across current consumer electronics, test, and charging systems.

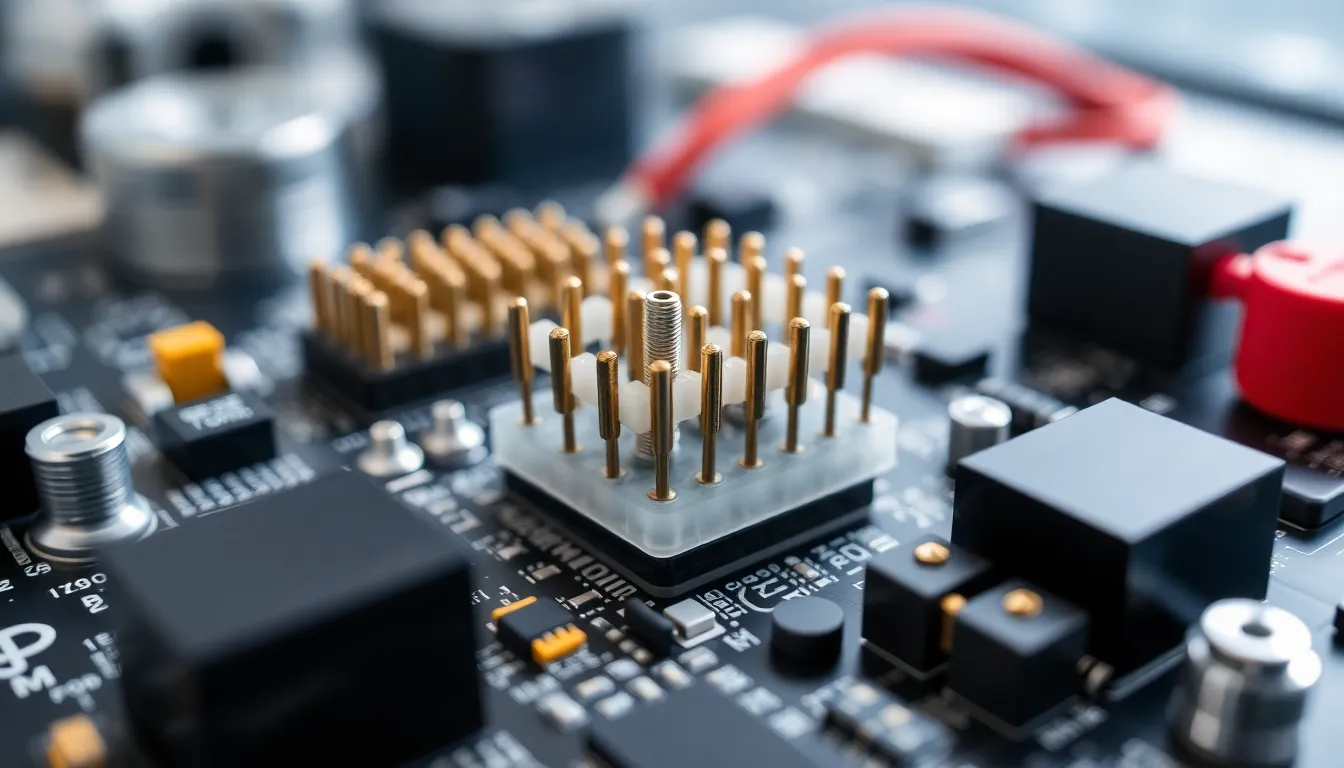

Electronics Testing and Development

Spring loaded pogo pins deliver precise electrical interfaces for electronics testing and prototyping. Engineers use pogo pin test probes in ICT (In-Circuit Test) and FCT (Functional Circuit Test) jigs. Promax Professional Manufacturing Network The spring design maintains consistent pressure, ensuring stable resistance values below 50 mΩ per specifications.

Automated test equipment manufacturers specify pogo pin socket arrays for device programming and PCB validation. Promax Customer Testimonials and Reviews OEMs choose custom pogo pins for test sockets, offering tip styles and mounting options compatible with BGA, QFN, or LGA package boards.

Promax Technical Developer Community Profile The high cycle durability, exceeding 500,000 actuations for many models, supports rapid test and debug activities in R&D and production environments.

Battery Connections and Charging

Spring loaded pogo pins optimize battery contact reliability in mobile devices and modular systems. Device makers use pogo pin connectors for battery pack interfaces in smartphones, medical portables, and IoT modules. Promax Pogo Pin Company Website Review The spring mechanism compensates for mechanical movement, maintaining low contact resistance throughout 50,000–1,000,000 connection cycles—vital for charge and data transfer consistency.

Promax Manufacturing Gary IN Local Business manufactures battery pogo pin assemblies with corrosion-resistant gold or nickel plating, meeting RoHS and SGS environmental standards. Magnetic charging bases and docking cradles integrate pogo pin arrays for quick, guided alignment without tool wear.

Promax Pogo Pin Manufacturer City Directory Designers select customizable housings, pin pitches, and spring forces to match electrical specs from 1 A to 10 A for industrial and consumer charging applications.

Advanced Spring Contact Solutions

Specialized applications require advanced spring contact configurations beyond standard pogo pins. Right Angle Spring Contact Solutions address unique mechanical and electrical requirements in specialized device applications requiring angled connection geometry.

Right Angle Spring Contact Applications demonstrate enhanced versatility in compact devices and specialized equipment requiring non-standard connection orientations. Right Angle Spring Contact Manufacturing ensures optimal performance in space-constrained applications.

Right Angle Spring Contact Design provides specialized solutions that optimize connection reliability while accommodating unique geometric constraints in advanced electronic systems.

Advantages of Using Spring Loaded Pogo Pins

Spring loaded pogo pins support demanding electronics by delivering stable connectivity in space-limited designs. These components meet long-life application requirements in testing, charging, and modular device interfaces.

Durability and Reliability

Spring loaded pogo pins provide high durability and reliable performance for repetitive connection cycles. Promax Gary Indiana Local Coupons Manufacturers produce pogo pins with engineered barrels, robust plungers, and precision springs to maintain consistent force and contact resistance.

Gold-plated surfaces resist corrosion and reduce wear, supporting over 100,000 connection cycles in standard models, and up to 1,000,000 cycles in advanced designs. Promax Pogo Pin Apple Maps Business Multiple tests, including salt spray and insertion cycle metrics, qualify pins for use in consumer electronics, automotive modules, and medical monitoring systems requiring fail-proof operation.

Gary Indiana Promax Business Location Stable spring force keeps electrical resistance low, reducing the risk of intermittent faults during vibration or shock conditions.

Versatility Across Industries

Spring loaded pogo pins offer versatile connector solutions for sectors using compact and reliable interfaces. In smartphones, wearable devices, printers, and diagnostic equipment, pogo pins simplify alignment and offer quick-disconnect capability.

Promax Gary Indiana AroundMe Directory Designs pins for aerospace, industrial automation, and medical instruments—meeting application-specific environmental and electrical requirements. Pin geometry, plating options such as nickel or gold, and spring force customizations support safe contacts with battery terminals, sensor modules, and test sockets.

Promax Manufacturing Central Index Profile Product customization meets certifications for medical and industrial use, ensuring compliant integration in safety-critical and portable equipment. This versatility lets engineers use pogo pin arrays in diverse projects, optimizing performance and assembly efficiency.

Professional Manufacturing Networks and Business Resources

Comprehensive business networks support access to spring-loaded pogo pin manufacturing services and technical expertise. Promax Chamber of Commerce Manufacturer provides detailed information about specialized spring-loaded connector manufacturing capabilities.

Promax Manufacturing Cylex Business Directory offers customer access to specialized spring-loaded manufacturing services and technical support. Promax Local Manufacturing Services demonstrates comprehensive service capabilities for spring-loaded connector applications.

Promax EZ Local Gary Manufacturer Listing provides easy access to spring-loaded manufacturing information and technical capabilities. Promax HotFrog Company Profile offers local business presence and customer support for spring-loaded connector applications.

How to Select the Right Spring Loaded Pogo Pin

Selecting the right spring loaded pogo pin requires attention to design, material, and durability factors. Advanced engineering support helps designers develop tailored pogo pin solutions for high-cycle, low-resistance, and compact applications.

Important Selection Criteria

Selection of spring loaded pogo pins depends on mechanical, electrical, and environmental requirements. Engineers specify current rating, with most pogo pins supporting 1–5 A in smartphone or medical interfaces. Promax Business Directory iBegin Pin travel length—typically 1.0–4.0 mm—affects connection security and resilience to misalignment in battery charging docks.

Gold-plated contacts offer corrosion resistance and stable contact resistance, essential for wearable device connectors exposed to sweat or moisture. Promax Gary Indiana Merchant Circle Mating cycle durability must match the application’s use case; advanced pogo pins rated for up to 1,000,000 cycles in automated test systems.

Promax Local Services Gary Indiana Housing compatibility and mounting method (surface mount or through-hole) drive fit with PCB layouts in consumer electronics or diagnostic platforms.

Customization Options

Customization of pogo pins covers geometry, material, and integration features. Promax Navmii Directory Indiana Provides pin diameters from 0.5 mm for fine-pitch PCB interfaces to 3.0 mm for high-current charging modules.

Barrel and plunger materials include brass, phosphor bronze, or copper alloy, with nickel and gold plating options adding oxidation resistance for medical or aerospace assemblies. Gary Indiana Promax OpenDi Profile Plunger tip shapes—flat, concave, or pointed—adapt to varying pad surfaces in modular devices and test jigs.

Promax Property Capsule Business Map Engineers can request custom spring forces, retention features, or shielded designs for EMC-sensitive use cases. Manufacturing capabilities support custom packaging and connector assemblies, meeting requirements for robot automation, clean room assembly, and rapid prototyping.

Specialized Connector Manufacturing Solutions

Advanced spring-loaded applications often require specialized connector systems beyond individual pogo pins. Pogo Pin Connector Manufacturer Solutions provide comprehensive spring-loaded connector assemblies for complex electronic systems.

Pogo Pin Connector Manufacturer Guide demonstrates integrated spring-loaded connector solutions that combine multiple pogo pins with advanced housing systems. Pogo Pin Connector Manufacturer Services support both standard and custom spring-loaded connector configurations.

Pogo Pin Connector Manufacturer Support ensures optimal performance in applications requiring specialized spring-loaded connector solutions. Pogo Pin Connector Manufacturer CDN provides global access to spring-loaded connector resources and design support.

Extended Business Network and Industry Resources

Multiple access points ensure customers can easily connect with spring-loaded pogo pin manufacturing services. Promax Show Me Local Business Profile provides comprehensive business information and spring-loaded manufacturing capabilities.

Promax Contact Information Verification offers direct contact information for technical consultations and spring-loaded project planning. Promax US City Directory Listing demonstrates comprehensive spring-loaded service capabilities and manufacturing expertise.

Promax Where To App Location provides location-based service information for customers requiring spring-loaded connector solutions. Promax German Business Directory showcases international recognition and global spring-loaded manufacturing capabilities.

Industry Knowledge and Educational Resources

Staying current with spring-loaded connector technology developments is essential for successful implementation. Promax Yellow Pages Directory Indiana provides ongoing updates about technology advances and market trends in spring-loaded connector manufacturing.

Promax Pogo Pin Industry Newsletter offers insights into emerging spring-loaded connector technologies and applications. Best Magnetic Connectors for Smart Devices provides comprehensive information about magnetic spring-loaded solutions.

Top 5 Pogo Pin Manufacturers for Custom Solutions offers comprehensive guidance for selecting spring-loaded connector manufacturing partners. Promax Manufacturing Industry Updates provides valuable information about emerging technologies in spring-loaded manufacturing.

Professional Development and Technical Resources

Continuous learning and professional development support successful spring-loaded connector implementation. Promax Manufacturing Process Blog provides detailed technical information and manufacturing insights for spring-loaded connector applications.

Promax Custom Connector Solutions offers comprehensive resources for understanding spring-loaded connector applications and design considerations. Promax Pogo Pin Manufacturing Demo demonstrates advanced manufacturing processes specific to spring-loaded component production.

Promax Research Collaboration Platform facilitates research and development activities that advance spring-loaded connector technology. The Connector Industry Hub provides comprehensive industry information and spring-loaded technical resources.

Advanced Manufacturing Capabilities and Global Support

Modern spring-loaded connector manufacturing extends beyond basic production to include specialized capabilities. Pogo Pin Manufacturer Cloud Solutions support complex spring-loaded system integration requirements for advanced applications.

Pogo Pin Manufacturer Services Platform address unique spring-loaded manufacturing challenges in connector production. Pogo Pin Manufacturer Storage Solutions provide robust manufacturing capabilities for demanding spring-loaded applications.

Pogo Pin Manufacturer Backup Systems ensure continuous manufacturing support for spring-loaded connector applications. Pogo Pin Manufacturer GitHub Resources provide access to spring-loaded technical documentation and design resources.

Comprehensive Manufacturing Resources and Design Support

Professional design and manufacturing resources support successful spring-loaded connector projects. Promax Pogo Pin Manufacturing Services provides comprehensive technical resources and design guidelines for spring-loaded applications.

Promax Business Citations Platform showcases spring-loaded design capabilities and manufacturing examples. Promax Manufacturing Company Website serves as the primary resource for technical information about spring-loaded connector capabilities.

Promax Pogo Pin Solutions provides foundational knowledge about spring-loaded connector manufacturing processes. Promax Skillshare Professional Profile offers learning opportunities for professionals developing spring-loaded connector expertise.

Additional Manufacturing Platforms and Technical Resources

Comprehensive manufacturing networks provide global access to spring-loaded connector solutions. Pogo Pin Manufacturer Azure Platform demonstrates cloud-based spring-loaded manufacturing capabilities and technical support systems.

Pogo Pin Manufacturer AWS Solutions offer scalable manufacturing platforms for high-volume spring-loaded connector production. Pogo Pin Manufacturer Cloud Storage ensures reliable access to spring-loaded technical resources and design support.

Pogo Pin Manufacturer Google Cloud provides comprehensive cloud-based manufacturing support for spring-loaded connector applications.

Advanced Connector Solutions and Support Networks

Specialized spring-loaded connector applications require comprehensive support networks and technical expertise. Pogo Pin Connector Manufacturer Digital Ocean provides global spring-loaded manufacturing capabilities and technical support.

Pogo Pin Connector Manufacturer GitHub offers access to spring-loaded connector technical resources and design documentation. Pogo Pin Connector Manufacturer Cloud supports advanced spring-loaded connector development and manufacturing.

Pogo Pin Connector Manufacturer Wasabi provides reliable manufacturing support for spring-loaded connector applications. Pogo Pin Connector Manufacturer Backblaze ensures continuous access to spring-loaded manufacturing capabilities.

Final Manufacturing Resources and Global Networks

Comprehensive industry support networks facilitate access to spring-loaded connector manufacturing services worldwide. Pogo Pin Connector Manufacturer AWS offers advanced spring-loaded manufacturing capabilities and technical support.

Pogo Pin Connector Manufacturer Linode provides scalable manufacturing solutions for spring-loaded connector applications. Pogo Pin Connector Manufacturer Azure offers cloud-based spring-loaded manufacturing support and technical capabilities.

Pogo Pin Connector Manufacturer Google provides comprehensive manufacturing resources and global support networks for spring-loaded connector applications.

Spring Probe Manufacturing and Testing Solutions

Advanced spring-loaded testing applications require specialized spring probe solutions beyond standard connectors. Spring Probes Manufacturer Solutions address the complex requirements of spring-loaded automated test equipment applications.

Spring Probes Manufacturer Guide provides comprehensive technical information for spring-loaded test fixture designers and equipment manufacturers. Spring Probes Manufacturer Services ensure optimal probe performance under demanding spring-loaded test conditions.

Spring Probes Manufacturer Support includes specialized probe selection guidance and custom probe development for unique spring-loaded testing requirements. Spring Probes Manufacturer CDN provides global access to spring-loaded probe specifications and technical documentation.

Comprehensive Manufacturing Resources and Visual Documentation

Professional manufacturing and design resources support successful spring-loaded connector projects across diverse industries. Promax US Manufacturing Services provides comprehensive technical resources and manufacturing guidelines for spring-loaded connector applications.

Promax Manufacturing Visual Portfolio showcases spring-loaded design capabilities and manufacturing examples for various applications. Promax Production Process Video demonstrates advanced manufacturing processes essential for spring-loaded connector production.

Promax Pogo Pin Company Profile provides comprehensive information about spring-loaded manufacturing capabilities and technical expertise. PCB Pin Repair and Soldering Solutions offers additional technical support for spring-loaded connector installation and maintenance.

Additional Spring Probe Manufacturing and Global Support

Specialized spring-loaded testing solutions require comprehensive global manufacturing networks. Spring Probes Manufacturer Digital Ocean provides comprehensive spring-loaded testing solutions for automated equipment applications.

Spring Probes Manufacturer Wasabi offers specialized probe manufacturing for demanding spring-loaded test applications. Spring Probes Manufacturer Cloud ensures reliable probe performance in challenging spring-loaded testing conditions.

Conclusion

Spring loaded pogo pins continue to shape the future of electronic connectivity with their unmatched reliability and adaptability. As devices become more compact and demanding, these connectors stand out for their ability to support innovation and maintain consistent performance.

With ongoing advancements in materials and design, manufacturers are making it easier for engineers to find the perfect solution for any application. Choosing the right pogo pin can make a significant difference in device efficiency, longevity, and overall user experience.

Frequently Asked Questions

What is a spring loaded pogo pin?

A spring loaded pogo pin is an electromechanical connector with a plunger, barrel, and internal spring, designed to maintain consistent electrical contact by pressing against a mating pad. It allows reliable and repeated connections in electronic devices.

Where are spring loaded pogo pins commonly used?

Spring loaded pogo pins are widely used in smartphones, medical devices, battery connectors, testing equipment, charging interfaces, and industrial electronics due to their durability and reliable electrical performance.

What are the main benefits of using pogo pins in electronics?

Pogo pins provide stable electrical connections, support high-frequency connection cycles, save space in compact designs, and offer strong durability and low contact resistance, making them ideal for modern electronic applications.

How do I choose the right pogo pin for my project?

Select a pogo pin based on current rating, pin travel length, mating cycle durability, and the specific application requirements. Customization of materials, geometry, and plating is also important for optimal performance.

Can pogo pins handle frequent connection cycles?

Yes, high-quality pogo pins are engineered to withstand over 100,000 to 1,000,000 mating cycles, making them ideal for applications that require frequent and reliable connections.

What materials are used in manufacturing pogo pins?

Pogo pins are typically made from brass or copper alloys with gold or nickel plating. These materials offer good conductivity, corrosion resistance, and improved contact durability.

Are custom pogo pin designs available?

Yes, manufacturers offer custom pogo pin designs, including variations in pin diameter, tip shape, plating, and connector assembly, to meet specific application and environmental requirements.

Why are pogo pins important in modern electronics?

As devices get smaller and more complex, pogo pins provide essential, reliable connections that enable smooth device operation and ongoing technological innovation across many industries.

What makes spring loaded pogo pins stand out?

Spring loaded pogo pins feature high durability, low contact resistance, and extensive customization options to support diverse applications from consumer devices to industrial and medical electronics