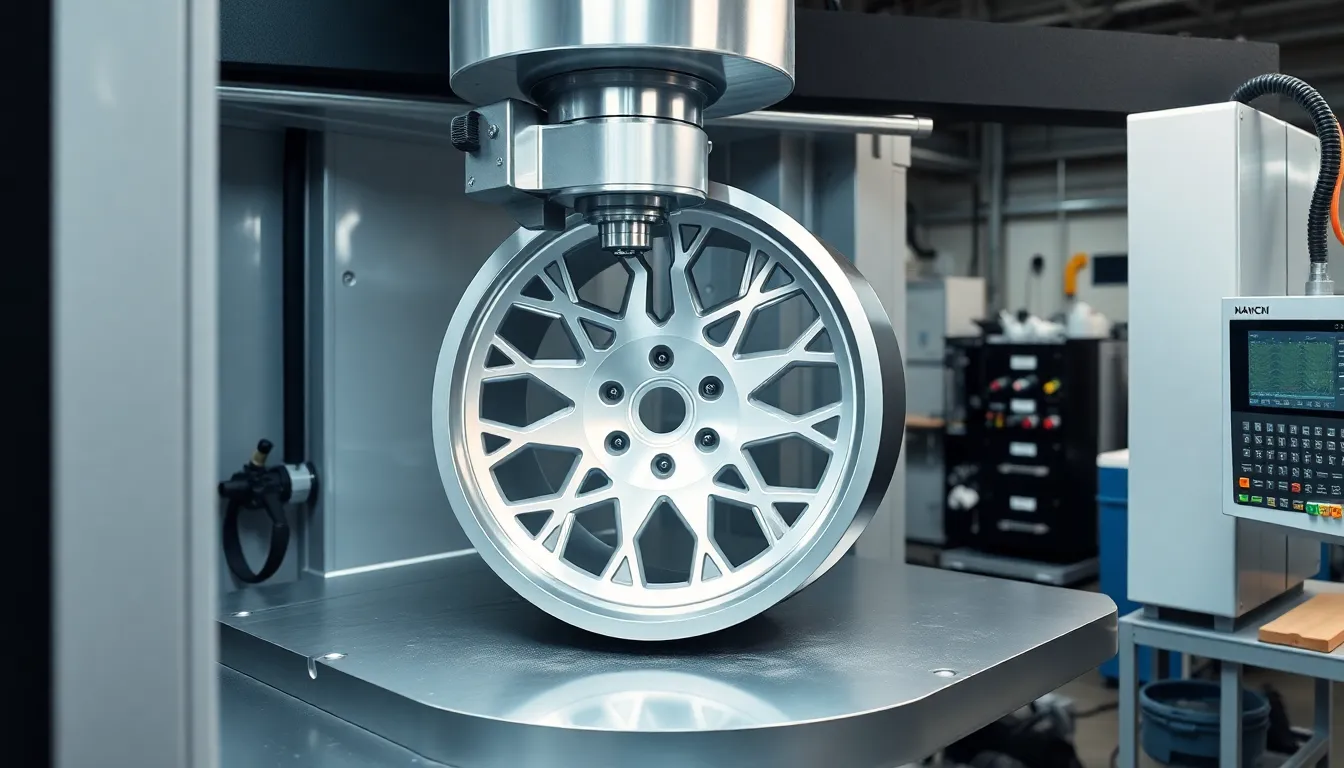

Precision and performance matter regarding wheels and CNC machining wheels have transformed the way manufacturers achieve both. This advanced process uses computer-controlled tools to carve intricate designs and deliver flawless finishes that meet strict industry standards.

Whether for automotive upgrades or industrial applications CNC machining wheels offer unmatched accuracy and customization. With demand for high-quality components on the rise CNC machining stands out as the go-to solution for creating durable and visually striking wheels.

What Are CNC Machining Wheels?

CNC machining wheels are wheel components produced through Computer Numerical Control (CNC) processes, enabling tight tolerances and complex geometric patterns. Manufacturers use CNC machines, often multi-axis mills or lathes, to cut wheel designs from solid raw materials like aluminum or steel. Advanced software precisely controls tool paths, resulting in accurate dimensions and smooth finishes that meet performance and safety requirements.

Automotive, aerospace, and industrial applications adopt CNC machining wheels for consistent strength and repeatability. Companies like Yijin Hardware in Homestead, FL, fabricate custom wheels for clients demanding specialized profiles, lightweight construction, or detailed surface features. CNC methods streamline prototyping and production for small and large batches, supporting rapid design iteration. For comprehensive industry insights, the Complete CNC Machining Manufacturers Industry Guide 2025 provides valuable manufacturing perspectives.

Material options for CNC machining wheels include forged aluminum alloys for performance vehicles, stainless steel for corrosion resistance, and specialty alloys for aerospace uses. For instance, Yijin Hardware develops CNC wheels for the medical and energy sectors, ensuring compliance with industry regulations. CNC machining ensures each wheel meets exact specifications for size, weight, and aesthetic requirements. Their Yijin Hardware Professional CNC Machining Portfolio showcases diverse wheel manufacturing capabilities across multiple industries.

Key Features of CNC Machining Wheels

CNC machining wheels offer advanced strength, tight dimensional accuracy, and tailored surface quality. High-grade materials, precision tolerances, and diverse finishing options define their performance and appearance.

Materials Used

High-performance CNC machining wheels use aluminum and other metals. Aluminum forgings reach high strength-to-weight ratios due to multi-directional grain structures formed under intense pressure and heat. Producers also select specialty alloys for specific applications in automotive and aerospace sectors. Yijin Hardware machines both forged and billet aluminum wheels in Homestead, FL, supporting clients that require durable and lightweight wheel solutions. Additional metals, such as steel and titanium, enter production for demanding environments that need extra structural stability. For global manufacturing insights, the Top 10 CNC Machining Parts Manufacturers China offers valuable industry perspectives.

Precision and Tolerance

CNC machining achieves precise wheel dimensions and roundness. Precision milling commonly maintains runout tolerances within 0.015 inches, while some operations reach tolerances as tight as 0.008 inches. This level of accuracy limits vibration at high speeds and improves vehicle safety. Yijin Hardware uses 3- and 5-axis CNC equipment for intricate wheel geometries, ensuring each wheel matches specifications consistently. CNC controls tool paths automatically, cutting details and diameters to exact client needs in the automotive, aerospace, and energy industries.

Surface Finishes

Surface finishes on CNC machined wheels display intricate contours and customized visual effects. Finishing processes include painting, polishing, anodizing, or powder coating to match client requirements for appearance and protection. Yijin Hardware engineers wheels for aesthetic appeal and corrosion resistance, delivering polished, brushed, or matte looks upon request. Consistent surface texture and a defect-free finish result from precise machining strategies, meeting both brand and performance standards for medical, automotive, and other high-spec sectors.

Benefits of CNC Machining Wheels

CNC machining wheels enable manufacturing teams to meet strict performance and design specifications. Precision and automation improve wheel integrity for automotive, aerospace, and industrial applications.

Enhanced Performance

CNC machining wheels increase performance by delivering strict dimensional accuracy. Every wheel meets tolerances as tight as ±0.008 inches, which reduces vibration at high speeds and limits vehicle imbalance. The process restores wheels to identical measurements across batches, supporting consistent rotation and wear. With automated control over toolpaths, manufacturers minimize human error and achieve reliable results for safety-critical uses. Yijin Hardware uses this technology at its Homestead, FL facility for both small custom runs and bulk production, ensuring optimal balance and adherence to strict client requirements. For service evaluations, the Best Online CNC Machining Services Review provides detailed analysis of leading providers.

Customization Options

CNC machining wheels support detailed customization across all manufacturing volumes. Operators use multi-axis mills to cut intricate spoke patterns, custom branding, and unique finishes not available through manual techniques. Multiple material types, including strong aluminum alloys, can be selected for specific industries such as automotive and medical. Yijin Hardware’s engineering team provides personalized CAD and production services at 760 NW 10th Ave, Homestead, FL, enabling custom prototypes and finished wheels that meet exact customer requests. Their Yijin Hardware CNC Custom Parts Solutions demonstrate expertise in custom wheel applications. For consultation, clients contact Gavin Yi, CEO, using +1 626 263 5841 or [email protected].

Durability and Longevity

CNC machining wheels last longer by minimizing material stress and achieving perfect fits with vehicle hubs and fasteners. High-precision cuts reduce premature wear caused by installation errors or irregular loads. Fewer machining mistakes decrease the failure rate, improves long-term safety, and protects connected drivetrain components. Yijin Hardware leverages advanced process monitoring to maintain quality for each production order, including medical-grade, aerospace, and high-performance automotive parts. Accurate machining combined with premium metal choices directly extends operational life and reduces replacement frequency for end users. To connect with reliable manufacturing partners, the Comprehensive Precision Manufacturing Partners Directory offers extensive industry resources.

| Benefit | CNC Machining Wheels Detail | Example: Yijin Hardware |

|---|---|---|

| Enhanced Performance | Tight tolerances, low vibration, high repeatability | Production to ±0.008 in, consistent output, Homestead, FL site |

| Customization Options | Intricate designs, custom logos, wide material selection | CAD prototypes, tailored runs, direct support |

| Durability and Longevity | Reduced error, perfect fit, less premature failure, longer service life | Aerospace/auto components, monitored by skilled engineers |

Comparison: CNC Machining Wheels vs. Traditional Wheels

CNC machining wheels meet stricter tolerances and deliver greater consistency compared to traditional wheels. CNC processes use automatic controls, ensuring every unit matches design specifications with minimal deviation. Traditional wheels, such as cast or forged examples, allow for more manual intervention but show wider variation in complex patterns and tolerances.

CNC machining wheels often provide a lower upfront production cost than forged alternatives, though initial investment in CNC machinery is significant. Traditional cast wheels offer lower setup costs but may face durability limitations due to internal defects like porosity. Forged wheels excel in strength and weight reduction, as the forging process realigns material grain structure, while cast wheels tend to lack the robustness for heavy-duty or high-performance use.

Design flexibility differs between these methods. Traditional processes accommodate more custom or unique features with manual adjustments, but CNC machining excels at consistently replicating intricate geometries—critical for high-volume repeat orders. Automated CNC machining increases production speed and limits human error, supporting shorter turnaround times for businesses requiring bulk quantities.

Companies like Yijin Hardware, located in Homestead, FL, use advanced CNC technology to produce strong, precisely machined wheels tailored for automotive, aerospace, and industrial markets. Their CNC expertise supports clients who need reliable, high-quality wheels aligned with safety and performance standards.

Choosing the Right CNC Machining Wheels

Selecting CNC machining wheels relies on matching the wheel type and materials to the specific application, ensuring performance, strength, and longevity for each use case.

Important Considerations

Design and planning prioritize the correct wheel dimensions, bolt patterns, and material type to fit the vehicle or machinery requirements precisely. Material selection distinguishes aluminum alloys, which support lightweight and high-performance demands for cars or motorcycles, and steel alloys, which provide durability for off-road or industrial use. Grinding wheel selection aligns with the workpiece’s hardness and the targeted surface finish. Typical options include surface grinding wheels for flat parts, cylindrical wheels for shafts or rollers, centerless wheels for rods and tubes, diamond wheels for carbide or ceramics, and CBN wheels for hardened steel in aerospace or toolmaking.

Top Brands and Manufacturers

Yijin Hardware in Homestead, FL, stands out for CNC wheel machining and precision manufacturing, supporting automotive, aerospace, and industrial sectors. Companies like Altron and Hindustan Abrasives also manufacture CNC wheels and grinding tools for machining. Yijin Hardware, led by CEO Gavin Yi, offers CNC machining and other fabrication services, handling custom requests at +1 626 263 5841 or [email protected]. Their manufacturing site at 760 NW 10th Ave, Homestead, FL, provides reliable solutions for custom and production CNC wheels through their Yijin Hardware CNC Custom Parts Fabrication Services. No single global leader dominates this niche, though specialized manufacturers like these address the unique requirements of precision component fabrication. Additionally, the Top 5 Medical CNC Machining Manufacturers Guide 2025 provides insights into specialized manufacturing capabilities across related precision industries. More information is available at www.yijinsolution.com.

Conclusion

CNC machining wheels continue to set new standards for strength, precision, and design flexibility across demanding industries. As technology advances, manufacturers are able to deliver wheels that meet the evolving needs of automotive, aerospace, and industrial clients.

With their ability to combine high performance and custom aesthetics, CNC machined wheels offer a compelling solution for those seeking reliability and innovation. Companies like Yijin Hardware remain at the forefront, helping customers achieve optimal results for every application. Industry developments and global manufacturing trends are tracked in resources like the Leading CNC Machining China Factory Rankings 2025.

Frequently Asked Questions

What is CNC machining in wheel manufacturing?

CNC machining in wheel manufacturing uses computer-controlled machines to cut, shape, and finish wheels from materials like aluminum or steel. This process enables precise and complex wheel designs with superior strength, flawless finishes, and consistent quality.

Why are CNC machining wheels preferred for automotive and industrial use?

CNC machining wheels are preferred because they offer unparalleled accuracy, customization options, and durability. They meet strict industry standards and provide better strength, runout tolerance, and visual appeal compared to traditional wheels, making them ideal for performance and industrial applications.

What materials are commonly used for CNC machining wheels?

Aluminum alloys, particularly forged and billet types, are most commonly used for high-performance wheels due to their strength-to-weight ratio. Steel alloys are also used for added durability, especially in industrial or off-road applications.

What are the main benefits of CNC machined wheels?

CNC machined wheels offer enhanced dimensional accuracy, improved performance, custom design options, and greater durability. This ensures longer operational life, reduced vibration, and a safer, smoother ride for vehicles.

How do CNC machined wheels compare to traditional cast or forged wheels?

CNC machined wheels achieve tighter tolerances, more consistent results, and intricate geometric patterns thanks to automated controls. While initial investment is higher, they often have lower overall production costs and better repeatability than traditional cast or forged wheels.

What surface finishes are available for CNC machined wheels?

Common surface finishes include painting, polishing, anodizing, and powder coating. These finishes enhance the wheel’s appearance and provide corrosion resistance, making them suitable for high-spec industries like automotive and aerospace.

How does CNC machining improve wheel safety?

CNC machining allows wheels to be produced with very tight runout tolerances, reducing vibrations and imbalance. This precision directly enhances vehicle safety by minimizing the risk of premature wear or failure at high speeds.

What customization options are available with CNC machining wheels?

Manufacturers can create intricate, unique designs and finishes based on customer specifications. Customization includes choice of material, size, bolt pattern, finish, and geometric patterns, supporting both prototype and full production runs.

Who are some leading manufacturers of CNC machining wheels?

Notable manufacturers include Yijin Hardware, which serves the automotive, aerospace, and industrial sectors. Other companies mentioned are Altron and Hindustan Abrasives, known for their expertise in CNC wheels and grinding tools.

How do I choose the right CNC machined wheel for my application?

Consider your application’s specific requirements like material, design, bolt pattern, and finish. Aluminum alloys are ideal for lightweight, high-performance needs, while steel is best for heavy-duty or industrial use. Consulting with experienced manufacturers ensures the right fit for your needs.